High Pressure Laminate (HPL) Panels

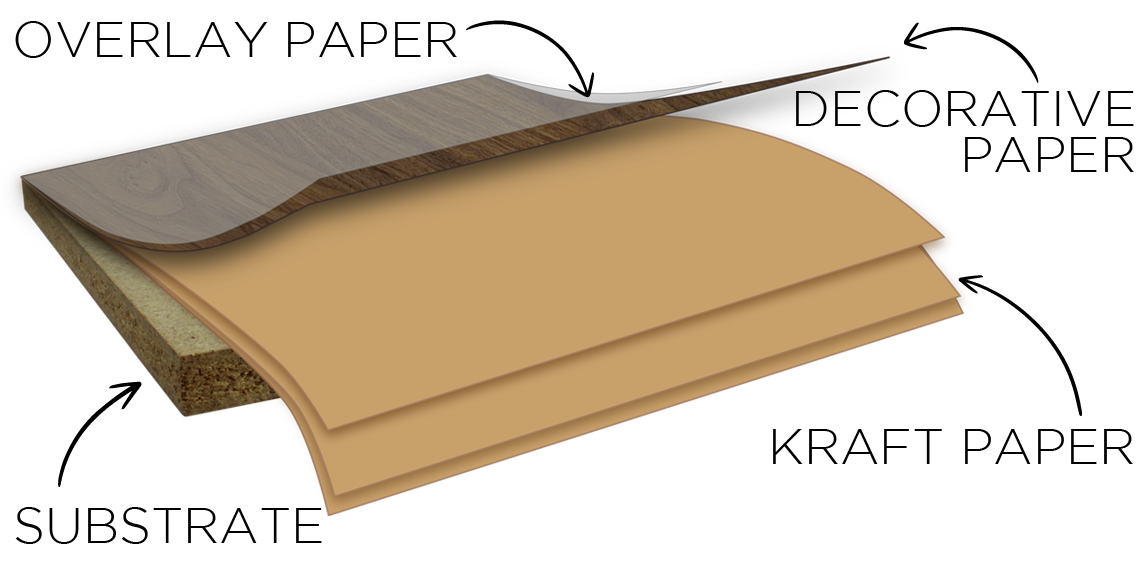

High Pressure Laminate (HPL) is a decorative surface that is both aesthetically pleasing and highly durable. Designed to withstand the wear and tear of daily use without losing any of its visual appeal, High Pressure Laminating is recommended for surfaces that are highly trafficked on a regular basis. Therefore, HPL is a great choice for applications in retail, hospitality, healthcare, and educational settings. Panel Processing offers multiple grades of High Pressure Laminate with useful features such as chemical resistance and wear resistance. We even carry fire rated laminates for applications that involve high fire risk.

TECHNICAL SPECIFICATIONS

- Sheet Sizes:

- 4′ & 5′ wide with various lengths available

- Thickness Available:

- 5.5mm (1/4″) – 1-1/4″

- Thousands of designs and colors available from our preferred suppliers listed below (minimums may apply)

- Including our exclusive Crater Lake Collection – 9 colors with 3 textures (see below)

Downloads

Get to Know Our Collections

OUR EXCLUSIVE HPL COLLECTION

NINE COLORS, TWO NEW TEXTURES

The Crater Lake Collection is Panel Processing’s HPL collection hailing inspiration from our facility in Klamath Falls, Oregon. The colors and textures embrace the strong natural elements that are inspired by Crater Lake and the surrounding area.